-40%

2500W ZVS Induction Heater Board + heating coil + Crucible + Water Pump + Power

$ 78.66

- Description

- Size Guide

Description

2500W ZVS Induction Heater Induction Heating PCB Board Heating Machine Melted Metal + Coil Mayitr+ Crucible+Pump+Power SupplyProduct size: 120mm * 240mm

Input voltage: 12V-48 recommended above 36V

Power requirements: less than 12V ≥ 10A 15V or more ≥ 20A

Maximum power:

2500W

Maximum current: 50A

For induction heating, it is recommended to use a switching power supply of 48V50A or higher. If the power supply is 24V or more, a power supply of 20A or more is required. The higher the voltage, the larger the current, the higher the heating power, the faster the heating speed.

F

eature:

[1] The heating plate is made of 240*120mm military grade PCB, and the performance is stable;

[2] The power line is fully covered with copper cover design, which can increase current and generate less heat;

[3]Using an oversized and large power heat sink, the heat dissipation is better;

[4] The output uses three M4 copper columns in parallel, which can be connected to other outputs such as high voltage packages;

[5] Six IRFP260 and 12 capacitors are used in parallel resonance, which has high power efficiency;

Packing Include

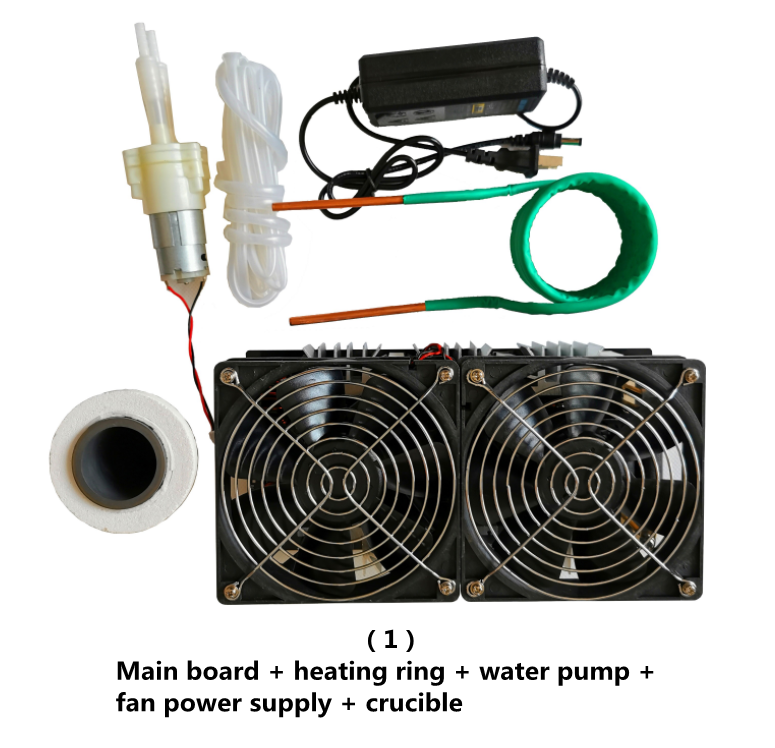

(1)

1 x fan

power supply

1x

heating ring

1 x PCB Board

1x water pump

1 x crucible

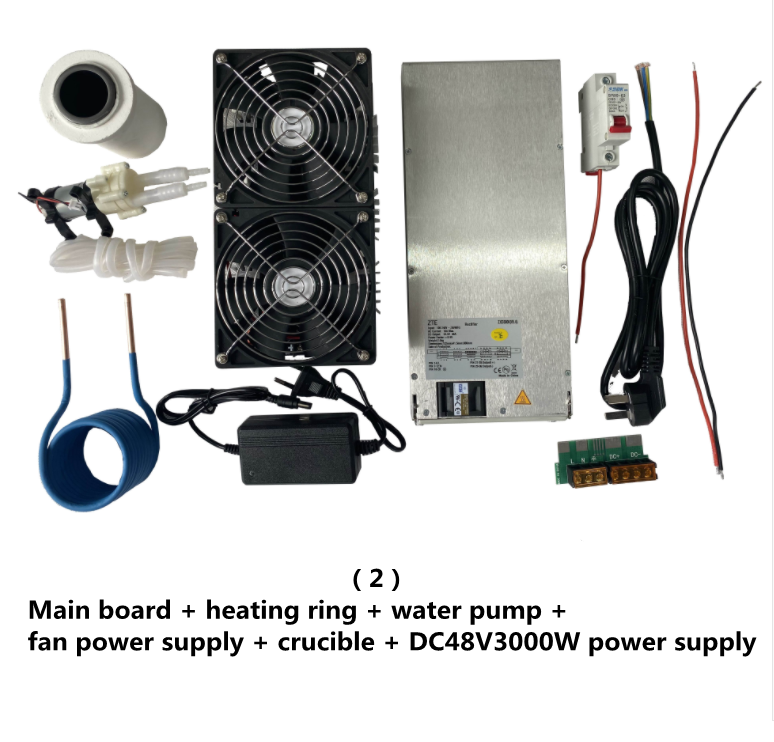

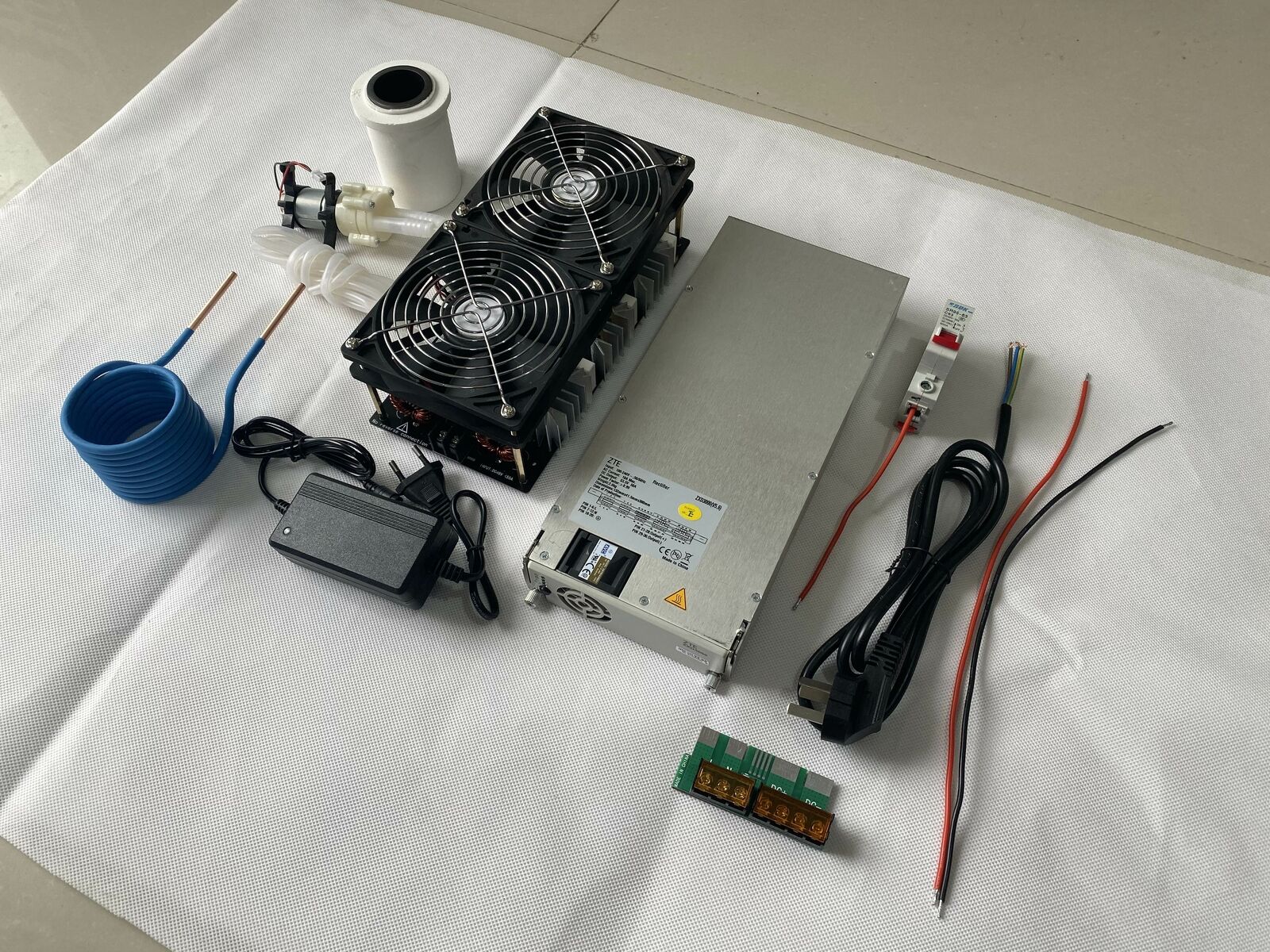

(2)

1 x fan

power supply

1x

heating ring

1 x PCB Board

1 x 48V 3000W power supply

1x water pump

1 x crucible

Buyers must see / pay special att

ention

[1] The power of induction heating is very large. In addition to the heat generated by the board and components, the heat generated by the copper tube is also very large. Buyers can bring their own water-cooled cooling system. You can buy a small water pump and a rubber hose with an inner diameter of 4mm or 2m. You can also purchase a matching water pump in the package.

[2] It must be noted when using a switching power supply, because a high-power switching power supply generally has a slow-start function, that is, it slowly rises when the output voltage starts, and if the voltage rises to 10V, the induction heating circuit is turned on because If the voltage is not enough, the circuit will not vibrate, so that the two MOS tubes are turned on at the same time to burn the components. Therefore, it is necessary to connect the induction heating circuit after the switching power supply voltage is stable;

[3] When heating metal objects, try not to heat the metal with too much volume. Otherwise, the overload may occur due to power overload. It is better to add a 50A fuse or ammeter and air switch whe

n using.

[4] Although this driver board can withstand more than 50A current, it is recommended not to exceed 48V55A in order to prevent accidents and damage for long-term continuous operation.

[5] The heating coil of the package has a diameter of 60mm and a design voltage of 86V. If a voltage of 40V or more is used, the heating coil with an inner diameter of 60mm or more must be used. The pump uses a 12V DC power supply. Please use the voltage regulator module to supply power separately to avoid burning the fan. Water pump.

[6] For induction heating, the copper tube in the package of this product should be used, or it should be wound according to the standard of 10 mm inner diameter of 60mm. Otherwise, the buyer will bear the responsibility for any burning problem.

[7] This heating module is designed to be used in environments above 2000W. If the working power is low, you can purchase the 1800W induction heating machine.

Precautions for use:

[1] This module has requirements for specific voltage and current. The voltage of 12V must be used above 10A. The power of the power supply will be too low, which will cause the actual output voltage of the power supply to be greatly reduced when the power is output. Below 12V, the two MOS transistors will be turned on at the same time, which will burn out the MOS tube;

[2] Some buyers will not notice the power requirement of the power supply when the MOS tube is heated. If the MOS tube is abnormally heated, first consider whether the output of the power supply meets the requirements.

[3] The board should not be unloaded, otherwise it will emit a high frequency of noise, and then the MOS tube will burn out.

[4] Induction heating is recommended to use 36V30A power supply, 12V power supply is too small to heat almost no reaction, and 12V power supply heating is likely to cause the power supply output voltage to drop, below 12V is very dangerous.

[5] Induction heating power is very large, and heat is inevitable, so be sure to dissipate heat.